PERMANENT MAGNETIC CONCENTRATOR SEPARATORS

APPLICATION:

PERMANENT MAGNETIC CONCENTRATOR SEPARATORS is widely

used for upgrading or concentrating material containing a very high percentage

of magnetics or where magnetic/mechanical agitation is required for the

separation of many difficult materials. It is ideal for the upgrading

of Sponge Iron/Cast Iron Borings, Steel/Brass/Aluminium turnings, Chips

and for minerals benefication application such as the purification of

dry ceramics and refactory materials, reclamation of abrasive grains,

removal of iron contamination from chemical powders and grains and for

many other such application requiring maximum separation with minimum

production loss etc..

DESCRIPTION:

The Separator basically consist of:

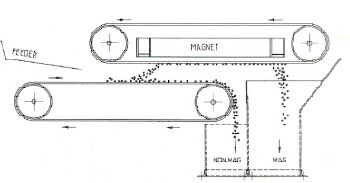

The Material to be treated is fed from the Vibratory Feeder on to lower belt where after travelling a short distance it comes under the Belt Conveyor. The upper belt conveyor runs under the series of Powerful Permanent Magnets arranged in such a manner so that the material is exposed during its travel through a number of magnetic fields of alernating polarity. Due to the continuous repetative agitation of the material non magnetic material falls back on the lower conveyor belt, while the magnetic material is retained on the upper conveyor belt due to force of magnetic attraction. The Separated material are carried and deposited in to the respective magnetic and non-magnetic discharge chutes.

- An electromagnetic Vibratory Feeder (with sub-hopper) which provides steps less regulation of feed for even flow.

- Two Conveyor belts The Upper belt running ahead of the lower conveyor belt and in the same direction.

- Permanent Magnetic Unit for picking Tramp Iron.

- Magnetic and Non-Magnetic collection Hopper.

- The Drive.

- The Supporting Structure.

The Material to be treated is fed from the Vibratory Feeder on to lower belt where after travelling a short distance it comes under the Belt Conveyor. The upper belt conveyor runs under the series of Powerful Permanent Magnets arranged in such a manner so that the material is exposed during its travel through a number of magnetic fields of alernating polarity. Due to the continuous repetative agitation of the material non magnetic material falls back on the lower conveyor belt, while the magnetic material is retained on the upper conveyor belt due to force of magnetic attraction. The Separated material are carried and deposited in to the respective magnetic and non-magnetic discharge chutes.

MANUFACTURING RANGE:

The Separator is available in a wide range of sizes

and capacities upto approx 100TPH and 650 mm belt width upto 2000 mm belt

width.

OPTIONS AVAILABLE AT EXTRA PRICE

- A variable speed drive motor can be furnished in place of the slandered constant motor if varied products are to be handled.

- The build-in motor and feeder starter can be furnished separately for remote mounting where remote control is desired.

- Multiple stage units can be supplied for unusually difficult materials.

- Other sizes on request.

NOTE:

Technical data specification subject to change.

# special Concentrator Separator can be made on request, please send us Your's technical data and application, required for our Engineers to provide.

# special Concentrator Separator can be made on request, please send us Your's technical data and application, required for our Engineers to provide.