CYCLIC MAGNETIC SEPARATORS

We are one of the pioneer companies engaged in manufacturing

and supplying the most celebrated quality of Cyclic Magnetic Separators,

which are made from superior quality raw materials for outstanding performance

of products. Our company, Star Trace has well-educated and experienced

professionals who carefully implementing latest technology and modern

machines to ensure quality products and customers' satisfaction. These

best performing products are available at very economic prices.

SPECIFICATIONS

Star Trace-HGMS Magnetic separators include magnetic

assembly separators include magnetic (magnetic coil, magnetic return frame),

canister with matrix and support structure, process flow distribution

system, process controller and instrumentation. A closed loop cooling

system may be provided for the magnet and power supply if suitable cooling

water is not available.

The system is provided with a fail-safe protection through thermal switches and a flow switch in the main cooling system; fail safe alarm triggering circuitry, operational in the events of component failure; and external interlocks to protect the system in the event of equipment failure. Power supply (rectifier) is built in accordance with the customer's requirements (voltage, frequency). Appropriate feed system and means for product collection and handling are provided by the customer or are available.

The system is provided with a fail-safe protection through thermal switches and a flow switch in the main cooling system; fail safe alarm triggering circuitry, operational in the events of component failure; and external interlocks to protect the system in the event of equipment failure. Power supply (rectifier) is built in accordance with the customer's requirements (voltage, frequency). Appropriate feed system and means for product collection and handling are provided by the customer or are available.

APPLICATION & PURIFICATION

Star Trace-HGMS magnetic separators have capability

to remove even very weakly paramagnetic materials. A number of extremely

effective applications include.

Clay Benefits:

High Gradient magnetic separator is unique in its ability to brighten clays be removing fine, weakly magnetic color body particles. This new technology may be used for:

Clay Benefits:

High Gradient magnetic separator is unique in its ability to brighten clays be removing fine, weakly magnetic color body particles. This new technology may be used for:

- Reduction of Fe2o3 in: glass sands; feldspars, barites

- Reduction of copper in molybdenum concentrates

- De-ashing and desulfurization of coal

- Phosphates upgrading

- Wet or dry separations

MANUFACTURING INDUSTRY, POWER GENERATION

- Filtration of feed water and condensates in nuclear and fuel power stations

- Recovery/recycling of lubricants and continuous removal of wear particles

INDUSTRIAL AND WASTE WATER

- Filtration of steel mill process and waste waters

- Purification of industrial and municipal waste waters

CHEMICAL FOOD AND PETROLEUM INDUSTRIES

Applications exist for STR HGMS magnetic separator

in the filtration of pregnant liquors, recovery and purification of catalysts

(wet or dry), other valuable materials.

CONCENTRATION

Successful beneficiation to final quality products

has been proved for rare earth minerals, beach sands and other minerals.

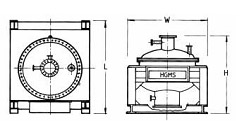

| Model | General Dimensions Dimensions in mm |

Approx system weight (ton) | ||

| L | W | H | ||

| ST - 22 - 15 - 5 | 1140 | 760 | 1370 | 0.770 |

| ST - 38 - 15 - 5 | 1320 | 840 | 1830 | 1.300 |

| ST - 56 - 15 - 5 | 1600 | 1120 | 1530 | 2.700 |

| ST - 76 - 15 - 5 | 1900 | 1420 | 1650 | 4.100 |

| ST - 107 - 15 - 5 | 2300 | 1800 | 1750 | 8.200 |

| ST - 157 - 15 - 5 | 2900 | 2450 | 2250 | 10.000 |

| ST - 214 - 15 - 5 | 3750 | 3000 | 2850 | 32.000 |

| ST - 305 - 15 - 5 | 5250 | 4100 | 3200 | 77.000 |

NOTE:

Technical data and specification subject to change.

# Special Cyclic Magnetic Separator can be made on request, customers have to just send their technical data and application required for our engineers.

# Special Cyclic Magnetic Separator can be made on request, customers have to just send their technical data and application required for our engineers.