NON FERROUS EDDY CURRENT METAL SEPARATORS

EDDY CURRENT SEPARATORS

STAR TRACE Eddy Current separation devices are an

effective way of removing non-ferrous metals from other products. Application

such as aluminium cans from municipal waste, aluminium flakes from shredded

PET, brass and aluminium from foundry sands and metals from shredded automobile

scrap. Other metals from shredded automobile scrap. Other metals such

as Lead can also be removed. For successful Non-Ferrous separation a magnet

should be installed prior to an Eddy Current Separator.

OPERATION PRINCIPLE:

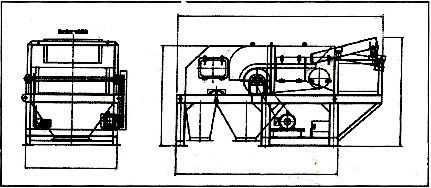

STAR TRACE EDDY CURRENT separator is ready to be

installed for separation. This separation utilizes a powerful Eddy Current

Rotor, Conveyor Belt, two variable discharge area and support frame. The

optional Vibratory Feeder provides a consistent flow of material to the

Eddy Current Separator.

EDDY CURRENT ROTOR

Star Trace Eddy Current Rotor utilizes an alternate

magnetic field for producing electrical currents in conductive metal.

The electrical current produces its own magnetic field around an object,

which opposes the magnetic field from the Eddy Current. This repulsion

diverts the object from the product stream. Mass, conductivity and density

influence the force and distance an object will repel.

EDDY CURRENT SEPARATION SYSTEM

Eddy Current Separation System manufactured and supplied

by Star Trace encompasses all the equipments above necessary to separate

non - ferrous metals and add ferrous metal separation equipment. It is

significant for removing ferrous metal prior to exposure to the Eddy Current

Separator. Strong magnetic field magnetizes and holds ferrous metal. The

Ferrous Metal will heat up and could burn holes in belt and cause significant

damage to the Eddy Current Rotors.

| Model | Rotor Motor | Belt Motor | Vibration Motor | Belt Width | A |

| ECMS - 300 | 5.5 Kw | 0.4 | 0.12 Kw * 2 | 450 | 975 |

| ECMS - 450 | 5.5 Kw | 0.75 | 0.12 Kw * 2 | 600 | 1125 |

| ECMS - 600 | 5.5 Kw/7.5 Kw | 0.75 | 0.12 Kw * 2 | 750 | 1275 |

| ECMS - 750 | 7.5 Kw | 0.75 | 0.25 Kw * 2 | 900 | 1425 |

| ECMS - 900 | 7.5 Kw/11 Kw | 1.5 | 0.4 Kw * 2 | 1100 | 1600 |

| ECMS - 1200 | 11 Kw | 1.5 | 0.4 Kw * 2 | 1400 | 1900 |

NOTE:

Technical data and specification subject to change.

# Special Non Ferrous Eddy Current Metal Detector can be made on request of customers, they have to just send technical data and application, required for our engineers.

# Special Non Ferrous Eddy Current Metal Detector can be made on request of customers, they have to just send technical data and application, required for our engineers.