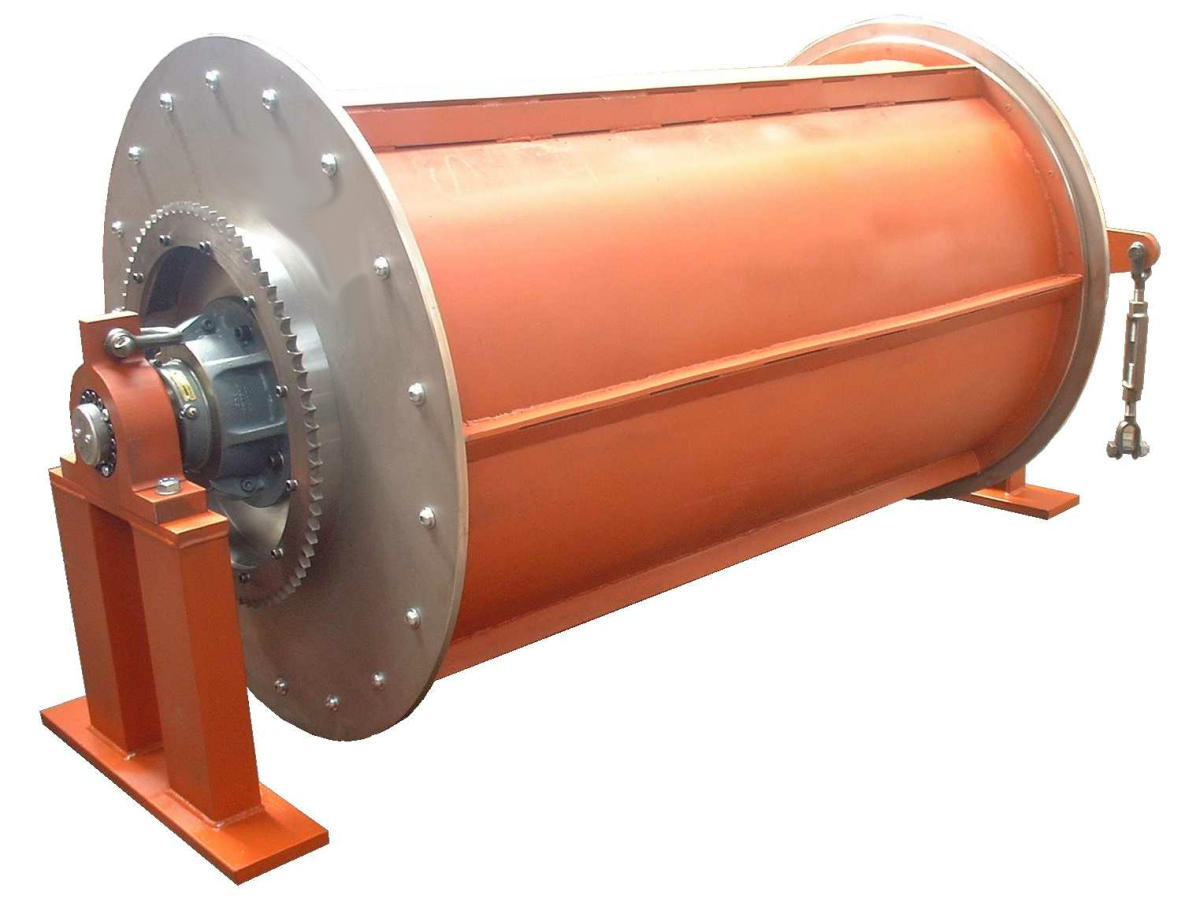

ELECTRO MAGNETIC DRUM SEPARATORS

A pioneer manufacturer and supplier of well advanced

Electro Magnetic Scrap Drum Separator. Star Trace always offers highest

quality products, which are manufactured using excellent raw materials

by skilled engineers. Star Trace Electromagnetic Drum Separator opens

the way to new efficiency in handling big volumes of large -size material

encountered in to day's material processing and mineral concentration

applications. The patented coil construction produces a much deeper field

than can be produced on electro or permanent pulleys or any other type

of magnetic drum separator.

In addition, the magnetic collecting pole area has been increased to give the drum greater ability to carry heavy magnetic loads. The surface holding force developed by this drum is also higher than any drum or magnetic pulley. Our company Electromagnetic Drum Separator does not only achieve better separation than was previously possible but also extends the range of magnetic treatment to meet larger.

In addition, the magnetic collecting pole area has been increased to give the drum greater ability to carry heavy magnetic loads. The surface holding force developed by this drum is also higher than any drum or magnetic pulley. Our company Electromagnetic Drum Separator does not only achieve better separation than was previously possible but also extends the range of magnetic treatment to meet larger.

TYPICAL APPLICATIONS

- Foundries

- Blast Furnace and BOF Slag

- Open Hearth Slag

- Dry Magnetite Ore Cobbing

- Auto Fragmentizing and Processing

FEATURES

- Deep, powerful magnet assembly, combined with high surface holding power

- Deep field pattern, improved surface area and greater magnetic pole area.

- Extended range of magnetic treatment.

- Simple installation and minimum space requirements

- Low DC power costs and extremely efficient performance

- Rugged construction for virtually maintenance-free operation

- Sealed cylinder O-ring construction a "must" for unprotected outdoor operation

- Heavy-duty, weatherproof manganese-steel cylinder

- Low drive HP requirements

- Steel support bearings

- Flexibility in application

DRUM SEPARATOR

StarTrace Type Drum Separators are the absolute

magnetic answer to heavy industrial applications such as tramp iron removal,

slag treatment, ore cobbing and scrap fragmentizing. The patented Star

Trace Drum Separator construction always introduces users with heavy-duty

materials processing and mineral concentration requirements to a new device

that offers superior separation capabilities than competing units. The

Drum Separator consists of an electromagnetic assembly mounted inside

an outer rotating drum assembly. The magnet assembly position may be adjusted

to meet varying feed and burden requirements. Its deeper magnetic field

pattern, improved surface holding force and greater magnetic pole area

achieves better separation than has previously been possible.

| Model | Dia Inches | Length Inches | Capacity(cu. M./hr.) |

| ST - EMD - 01 | 36 | 36 | 185 |

| ST - EMD - 02 | 36 | 48 | 265 |

| ST - EMD - 03 | 36 | 72 | 450 |

| ST - EMD - 04 | 42 | 54 | 280 |

| ST - EMD - 05 | 42 | 78 | 470 |

| ST - EMD - 06 | 48 | 42 | 385 |

| ST - EMD - 07 | 48 | 72 | 630 |

| ST - EMD - 08 | 60 | 60 | 750 |

| ST - EMD - 09 | 60 | 72 | 900 |

NOTE:

Technical data and specification subject to change.

# Special Electromagnetic Drum Separator can be made on request of customers, they have to just technical data and application, required for our engineers

# Special Electromagnetic Drum Separator can be made on request of customers, they have to just technical data and application, required for our engineers