HIGH GRADIENT MAGNETIC SEPARATORS

Star Trace, a leading and established company offering

an extensive range of High Gradient Magnetic Separators We incepted ourselves

with motto to manufacture and supply superb quality Magnetic Separators.

Today company has established in the field of High Gradient Magnetic Separator

manufacturing industry. Our company is assisted by industrially trained

professionals who hold specialization in this field. We offer these products

at marketing leading prices across India and other parts of world as well.

OPERATING PRINCIPLE

The principle (simplified) equation for the magnetic

attraction force on a particle is:

- Fm=Const. xVxXxHx grad H

- V is particle volume

- X is particle magnetic susceptibility

- H is magnetizing field grad H is magnetizing gradient

From this fundamental equation is evident that with

homogenous magnetic fields (grad H = 0) there is no resulting attraction

force on the left particle. This is illustrated where the left part show

the undisturbed and the right part a disturbed field. Field gradient is

show here by the varying distance between field lines. Any sharp edge

of small dimension will cause such a field distortion, and hence an increased

gradient. The famous illustration of this is an ordinary permanent horse-shoe

magnet and iron file achieving. Here the achieving will stick mostly to

the edge of the poles due to the increased gradient.

The Star Trace High Gradient Magnetic Separator design

is a reversal of a normal electric "bar" magnet. This overcomes many of

the imitations of working within the air gap of the conventional horse

a hoe shape. The most important advantage is that the return frame cross-section

can be increased to cope with higher field strengths without saturation.

The resulting homogenous magnetic field inside the

solenoid is then manipulated inserting varying types of matrices into

the canister. The type of matrix is a function of feed particle size.

For coarser particle (up to 1mm) a grid of expands metal is used, and

for very fine particle sizes (clay), steel wool is used. Matrix material

is either stainless steel or another ferromagnetic material. In this way

field strength, field gradients, and matrix flow-through capabilities

can be optimized for each case.

The magnetic separator is cyclic or discontinuous,

since it must be stopped and demagnetized for flushing out the trapped

magnetic particles. It use is therefore limited to feeds with low enough

magnetic content, to permit acceptable cycle times. For applications with

higher contents of magnetic a continuous variety of this principle, the

High Gradient Magnetic Separator carousel, is available.

OPTIMUM OPERATING CONDONES SHOULD BE ESTABLISHED FROM LAB TESTS ON REPRESENTATIVE SAMPLES.

Laboratory and small Pilot Scale Cyclic High Gradient

Magnetic Separator.

Our High Gradient Magnetic Separator Modes 10- 15- 20 10 cm bore Cyclic Laboratory and small pilot scale High Gradient Magnetic Separator is used in star Trace's standard laboratory tests to establish the separations conditions in mineral processing or purifications and water treatment problems. Determination of the combined effects of the systems operating variable on separation or filtration efficiency is required to minimize cost of a full scale system. This system is easily transportable for small scale on-site pilot testing.

Our High Gradient Magnetic Separator Modes 10- 15- 20 10 cm bore Cyclic Laboratory and small pilot scale High Gradient Magnetic Separator is used in star Trace's standard laboratory tests to establish the separations conditions in mineral processing or purifications and water treatment problems. Determination of the combined effects of the systems operating variable on separation or filtration efficiency is required to minimize cost of a full scale system. This system is easily transportable for small scale on-site pilot testing.

15 THP Continuous High Gradient Magnetic Separator

and Mineral Processing Pilot Plant.

The Star Trace- HGMS carousel Continuous High Gradient Magnetic Separator can process from 1 to 15 tons of one per hour. As part of Star Trace's mineral processing pilot plant, the Carousel may be incorporated in a flow sheet that includes crushing, grinding and classifying equipment. Thickeners permit the Carousel products to be rerun simulating multistage flow sheets. A pilot carousel may be leased separately for on-site pilot testing.

The Star Trace- HGMS carousel Continuous High Gradient Magnetic Separator can process from 1 to 15 tons of one per hour. As part of Star Trace's mineral processing pilot plant, the Carousel may be incorporated in a flow sheet that includes crushing, grinding and classifying equipment. Thickeners permit the Carousel products to be rerun simulating multistage flow sheets. A pilot carousel may be leased separately for on-site pilot testing.

MAGNETIC FILTERS

Star Trace - HGMS high gradient magnetic filters

are designs to remove ferromagnetic and ever weekly magnetic corrosion

products such as iron and copper from thermal power reticulating and process

waters at temperatures up to 400 C and pressures up to 275 bar. Corrosion

product reductions to less than 0.01 pp, have been obtained. Our company

High Gradient Magnetic Filter is cyclic, automatic back flushing filters

operating in alternate feed and flush modes. Typical duty cycle feed times

are days or weeks, flushing requires only fractions of a minute. Back

flush volumes are small and solids settle easily. As a protective measure,

feed flow to the filter may be bypassed during the flush cycle.

Star Trace filter systems have long service life with negligible maintenance. The magnetic filter has no moving parts to wear out and the fixed durable filter medium is either stainless steel or another ferromagnetic material chosen for its low corrosion factor. Standard sizes are the same as for the cycle HGMS range. Max capacity for size 214 is 800-4000m3/h pressure drops of less than 4 Bar.

Star Trace filter systems have long service life with negligible maintenance. The magnetic filter has no moving parts to wear out and the fixed durable filter medium is either stainless steel or another ferromagnetic material chosen for its low corrosion factor. Standard sizes are the same as for the cycle HGMS range. Max capacity for size 214 is 800-4000m3/h pressure drops of less than 4 Bar.

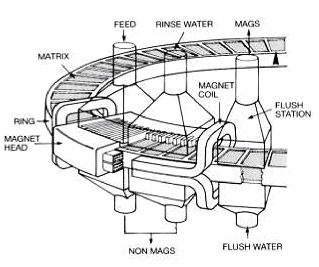

STAR TRACE HGMS CAROUSELS

SPECIFICATIONS

Basically the same as for the cyclic device, with

the exception that the magnet coil is flared at both ends to permit the

passage of the matrix ring. Rubber seals are used to prevent leakage in

the magnet head. Depend as per carousel unit.

ADVANTAGES

- Broad range of applications

- Fine particle processing

- High separation efficiency

- Simple, reliable design

- Non-clogging operations

- Easy flushing of magnetic (Patented backward flush)

- Low specific power consumption

- Low maintenance

- Long component life

- Minimal monitoring

- Large process capacity

- Insensitive to air/ water quality

APPLICATIONS

Star Trace High Gradient Magnetic Separator (HGMS)

carousel Magnetic Separators can be used for many applications including

the processing of iron ores, rate earth, industrial minerals, coal (desulfurization

and de-aching), and chemical waste. In addition to the strongly magnetic

compounds of Fe, Co, and Ni a vast number of more weakly magnetic compounds,

which are not normally treated by ordinary magnetic separation, may be

processed by high gradient magnetic separator.

STR- High Gradient Magnetic Separator (HGMS) are able to remove ever very weakly paramagnetic materials. A number of extremely effective applications includes: increase of the GEB of kaolin clay, reduction of copper in molybdenum concentrates and of Fe 2 O3 in sands, barites and ceramic clays; the purification of coal, materials and phosphates.

STR- High Gradient Magnetic Separator (HGMS) are able to remove ever very weakly paramagnetic materials. A number of extremely effective applications includes: increase of the GEB of kaolin clay, reduction of copper in molybdenum concentrates and of Fe 2 O3 in sands, barites and ceramic clays; the purification of coal, materials and phosphates.

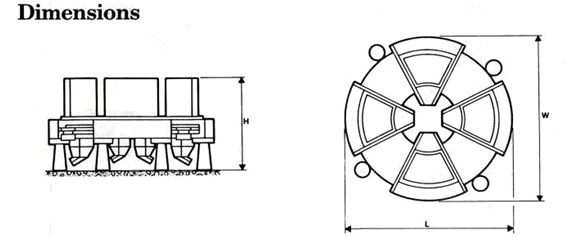

| Size | General dim in mm | Max no. of Mag Heads | Field Rating (Teela) | Power/ Head (Kw) | Baele Weight (ton) | Add Weight per Mag (ton) | Nominal Capacity/ Mag Head (ton/h) | ||

| L | W | H | |||||||

| 120 120 120 120 |

4000 4000 4000 4000 |

2000 2000 2000 2000 |

2000 2000 2000 2000 |

2 2 2 2 |

0.5 1.0 1.5 2.0 |

27 77 162 252 |

4.5 4.5 4.5 4.5 |

1.5 2.3 3.5 5.5 |

3 3 3 3 |

| 185 185 185 185 |

3700 3700 3700 3700 |

3400 3400 3400 3400 |

3300 3300 3300 3300 |

2 2 2 2 |

0.5 0.7 1.0 1.5 |

50 80 125 200 |

6.3 6.3 6.3 6.3 |

4.2 12.5 14.7 18.7 |

25 25 25 25 |

| 240 240 240 240 |

4700 4700 4700 4700 |

4500 4500 4500 4500 |

3300 3300 3300 3300 |

2 2 2 2 |

0.5 0.7 1.0 1.5 |

55 85 130 210 |

12.5 12.5 12.5 12.5 |

5.8 17.5 21 27.3 |

50 50 50 50 |

| 350 350 350 350 |

6000 6000 6000 6000 |

6000 6000 6000 6000 |

4000 4000 4000 4000 |

3 3 3 3 |

0.5 0.7 1.0 1.5 |

75 105 150 220 |

15 15 15 15 |

12 36 43 56 |

75 75 75 75 |

| 480 480 480 480 |

8000 8000 8000 8000 |

8000 8000 8000 8000 |

4500 4500 4500 4500 |

4 4 4 4 |

0.5 0.7 1.0 1.5 |

100 130 175 260 |

18 18 18 18 |

24 72 87 112 |

100 100 100 100 |

NOTE:

- Model designs for reduced power consumption and / or different field intensities are available.

- Model 120 and 185 are available with one or two heads: models 350 and 480 are available with one to four heads. Heads in the same unit can work parallel or in series and can be built for the same or different magnetic field intensities.

- Star Trace reserves the right to change the specifications.

NOTE:

Technical data and specification subject to change.

# Special High Gradient Magnetic Separator can be made on request, customers have to just send their technical data and application required for our engineers.

# Special High Gradient Magnetic Separator can be made on request, customers have to just send their technical data and application required for our engineers.