MAGNETIC COOLANT SEPARATORS

StarTrace is assisted by qualified professionals

who have specialization in manufacturing a wide range of Coolant Filtration

Systems. Our company has a team of highly dedicated professionals with

more than 25 years of experience have designed, developed, manufactured

and supplied filters to various industries. StarTrace filters are applied

in various industries like Engineering, Automobile, Bearings, Spindles,

Textile Machinery Rolling Mills, Wire Drawing, etc. We supply these filters

to both indigenous and imported Machines and also applied as original

fitment by many machine tool builders. The StarTrace offers an extensive

range of contemporary models filters. These model filters are chosen from

special/ larger system and can be designed and supplied as per requirement.

APPLICATION:

Magnetic Filters are ideally suitable for cylindrical,

Centerless, surface & internal grinding machines, thread grinders,

honing machines, rolling mills etc. It is also used as a pre-filter along

with other types of coolant filters like Paper Band or Hydro Cyclone filters.

The unit can be fitted on existing.

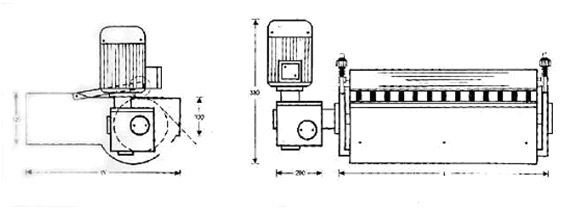

CONSTRUCTION & WORKING PRINCIPLE:

Magnetic Filter comprises of powerful magnetic drum

driver by double reduction worm geared motor. The contaminated coolant

from the machine is passed through the gap between the drum and body.

The dust particles are attached by the drum and a rubber roller squeezes

the swarf which is scrapped off which is scrapped off by a scrapper plate.

The clean coolant is collected is the coolant tank for recirculation to

the machine.

ADVANTAGES OF MAGNETIC FILTER:

- Removes ferrous particles from coolants.

- Improves surface finish on components.

- Increases coolant life & wheel life.

- Frequent cleaning of coolant tank is avoided.

- Can be used as a pre-filter for other filtration systems.

| MODEL | FLOW RATE Ltr/Min | L | W | MAGNETIC DRUM | RUBBER ROLLER | MOTOR H.P | |||

| DIA | LENGTH | SPEED rpm | DIA | LENGTH | |||||

| ST 50 | 50 | 225 | 400 | 120 | 185 | 2.5 | 60 | 185 | 0.25 |

| ST 70 | 70 | 300 | 400 | 120 | 265 | 2.5 | 60 | 265 | 0.25 |

| ST 100 | 100 | 400 | 400 | 120 | 365 | 2.5 | 60 | 365 | 0.25 |

| ST 150 | 150 | 530 | 450 | 120 | 490 | 2.5 | 60 | 490 | 0.50 |

| ST 200 | 200 | 630 | 500 | 120 | 590 | 2.5 | 60 | 590 | 0.50 |

| ST 300 | 300 | 830 | 525 | 120 | 790 | 2.5 | 60 | 790 | 0.50 |

| ST 500 | 500 | 630 | 500 | 150 | 590 | 2.5 | 80 | 590 | 0.75 |

| ST 1000 | 1000 | 830 | 525 | 150 | 790 | 2.5 | 80 | 790 | 0.75 |

| ST 1500 | 1500 | 1050 | 750 | 200 | 1000 | 2.5 | 100 | 1000 | 1 |

NOTE:

- Above flow rates are for water/soluble oil (emulsion) and for neat oil. flow rates will be lesser by appex.40%

- Magnetic filters cab be supplied with suitable tend & pump as per customers requirements.

- These units an also be supplied with Paper band or Hydro cyclone coolant filters.

NOTE:

Technical data and specification subject to change.

# Special Magnetic coolant separator can be made on request of customers they have to just send their technical data and application, required for our engineers.

# Special Magnetic coolant separator can be made on request of customers they have to just send their technical data and application, required for our engineers.